Warehouse Management System

Streamline, Scan, Succeed. Empowering warehouse efficiency, designed for SME logistics businesses

Warehouse Management System (WMS)

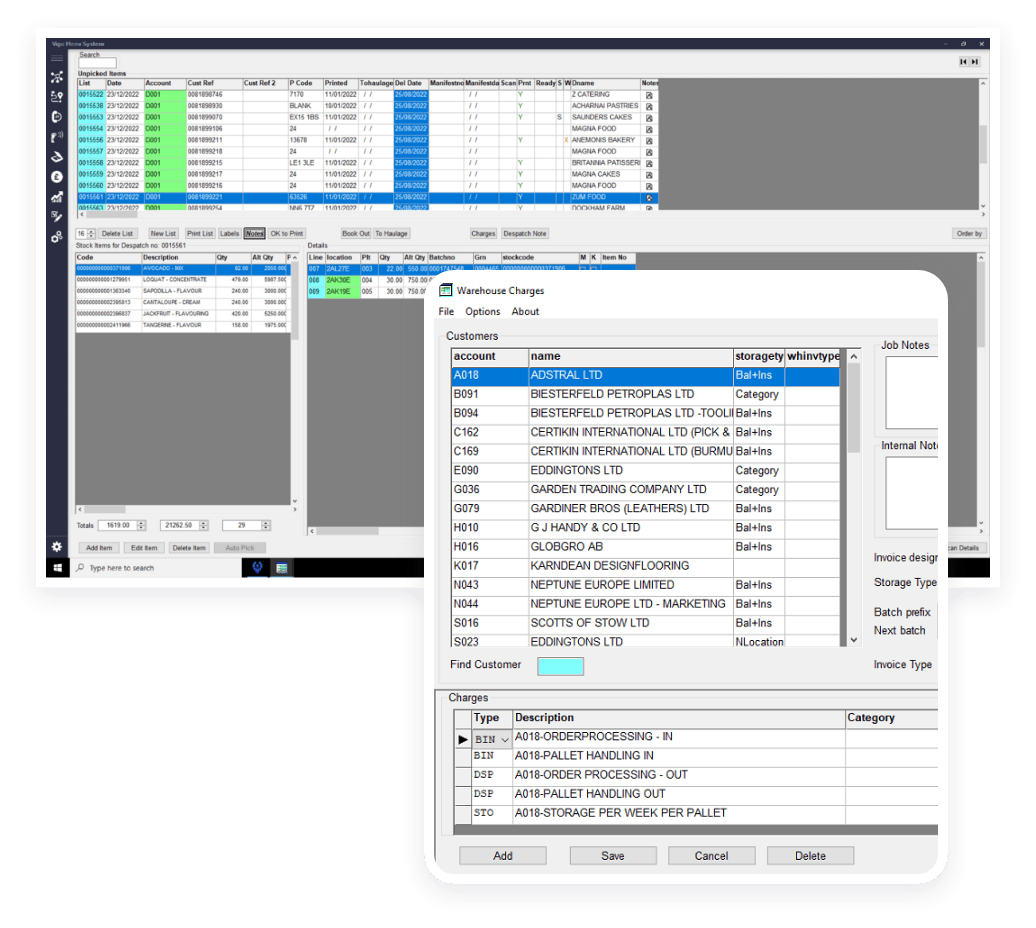

Vigo WMS is designed to simplify your warehouse processes, whilst providing real time management of inbound, storage, picking and despatch operations. When combined with our Mobile warehouse solution, the benefits realised are significant.

Your warehouse operation will become more efficient, profitable, and inventory turns will increase providing greater sales £ per square foot.

Our system is successfully in use across a wide range of logistics businesses, so if you are using paper based systems or overly complex and expensive WMS solutions, investing in our Warehouse Management System could save you time and money.

Fully integrated into our Transport Management System.

Mobile warehouse

Revolutionise your warehouse operations with our Mobile warehouse solution. Our state-of-the-art software seamlessly integrates with cutting-edge technology to optimise efficiency and accuracy. Say goodbye to manual processes and paperwork.

Our wireless synchronisation (WiFi or data SIM) ensures that order information is instantly available on handheld devices, allowing pickers to follow on-screen instructions to scan and fulfill orders with speed and precision. Experience unparalleled flexibility and mobility as you access real-time data on the go.

With our Mobile warehouse solution, you can eliminate inefficiencies and boost productivity by accessing critical information wherever you are in the warehouse.

Receive with ease

Are you tired of dealing with the complexities of managing your clients inventory? Are you constantly struggling to keep track of the goods coming into your business? If so, then it’s time to get your goods receiving under control.

GRNs are an essential tool for businesses that want to streamline their operations and improve efficiency.

Key features:

-

Validate all inbound delivery against expected client requirements

-

Allocate predefined bin locations and auto put-away rules

-

Various methods of inbound charging

-

Quality control and on hold processing

Store with accuracy

Achieve end to end stock visibility with full control from receipt to despatch.

Utilise cycle counting, blank bin reporting and ensures that your client’s inventory is always accurate. Provide real time visibility of inventory levels via the Client Portal.

Key features:

-

Aged stock reporting

-

Detailed traceability reports

-

Ad hoc and cyclic stock checks

-

On hold management

Pick efficiently

There are many inbound and outbound processes involved in moving and managing inventory that make up the discipline of warehouse management. Businesses often focus on outbound processes to increase customer satisfaction and reduce operational inefficiencies and costs.

But order picking is a crucial part of the outbound piece of warehouse management. It constitutes all of the steps involved in physically retrieving the items stored in the warehouse to fulfil a customer order.

Improvements in order picking help your business get the right products to customers faster, and spend less money on the associated steps.

Despatch seamlessly

With the WMS integrated into our TMS (Transport Management System), the warehouse orders can be labelled appropriately and handled by the Cross Dock Solution to ensure that the loading for despatch is seamless, whilst ensuring that your warehouse order outbound charges are applied.

Invoice with ease

Getting the right billing system in place for your Warehouse isn’t easy, Vigo WMS is designed for haulage, 3PL businesses.

-

Multiple rate cards for inbound receiving, despatch, pick charges, pallet, case, container de-stuffing, re-stack and more...

-

Storage charging weekly max, open balance plus inbound and more…

-

Invoice by email

-

Accounts integration

Benefits of our Warehouse Management System

Stock overview

Improve monitoring and management of obsolete stock whilst increasing stock turns and thus your revenues.

Cost savings

Reduce your operating costs and deliver tangible ROI on your WMS investment.

Optimise inventory

Improve inventory accuracy, save time and money, and improve contract service levels.

Increased productivity

Increase productivity with higher levels of throughput per operator.

Error reduction

Reduce costly errors, high inventory accuracy saves £1000s in lost time and claims whilst improving service levels.

Warehouse Management System (WMS) – FAQs

A Warehouse Management System (WMS) is a software solution that enables companies to efficiently manage and optimise their operations in the warehouse. It helps automates and streamlines processes such as inventory management, order fulfilment, picking & packing, shipping and returns.

By leveraging a Warehouse Management System (WMS), companies can gain improved visibility into their supply chains, better control of inventory levels and improved fulfilment rates. This leads to cost savings by reducing labour costs and optimising inventory space utilisation. Additionally, it helps improve customer satisfaction by providing real-time tracking of orders throughout the entire process.

Implementing a Warehouse Management System (WMS) requires careful planning and execution. Companies should first determine their specific needs by understanding how their current processes operate. This can help identify any existing issues or areas for improvement that need to be addressed with the new solution. After making these decisions, businesses must then select a suitable WMS solution based on their unique requirements; evaluate compatibility with other systems; plan for data migration; develop an appropriate training plan for staff; and test the system thoroughly before going live.

Choosing the right Warehouse Management System (WMS) may depend on the company’s unique needs, size, budget, and other requirements. Before making any decisions, it is important to do thorough research based on features offered, understand the total cost of ownership involved such as data migration and customisation costs, along with any ongoing maintenance costs and necessary integrations.

Companies that require high levels of accuracy when handling large volumes of stock typically benefit from implementing Warehouse Management System (WMS) solutions. This includes manufacturers, distributors, Third-Party Logistics providers (3PLs), ecommerce stores or any other business operating out of warehouses often require higher levels of accuracy when managing their inventory than what manual paper-based methods provide thus need sophisticated technology solutions like WMS to gain visibility into all stages of their supply chain operations and improve efficiency across each stage from procurement till delivery at the customer’s doorstep.